A Detailed Consider the Setup Process of Welding Examination Techniques

Welding examination is an important process that ensures structural stability and security. The installation of assessment techniques entails several methodical actions, each integral to attaining dependable results. From preparation and device option to conducting aesthetic and non-destructive examinations, each stage needs cautious interest. Comprehending these procedures can considerably improve high quality assurance in welding jobs. What obstacles arise in applying these techniques, and just how can they be effectively resolved?

Comprehending the Relevance of Welding Inspection

Welding assessment is a vital part of guaranteeing structural stability and safety and security in building and production procedures. This technique involves assessing bonded joints for issues, making certain that they satisfy specific criteria and laws. By methodically gauging weld high quality, examiners can recognize problems such as splits, voids, and insufficient combination, which can compromise the strength and resilience of structures.

The relevance of welding assessment expands past immediate security concerns; it aids prevent expensive failures and prospective hazards in the long-term. Effective evaluation techniques foster conformity with sector standards, thereby improving the total reliability of bonded components. On top of that, a durable assessment procedure adds to keeping the credibility of makers and home builders, as it ensures clients of the quality of their projects. Eventually, comprehending the significance of welding examination is important for advertising secure building practices and making certain the durability of essential infrastructure and products.

Picking the Right Equipment for Assessment

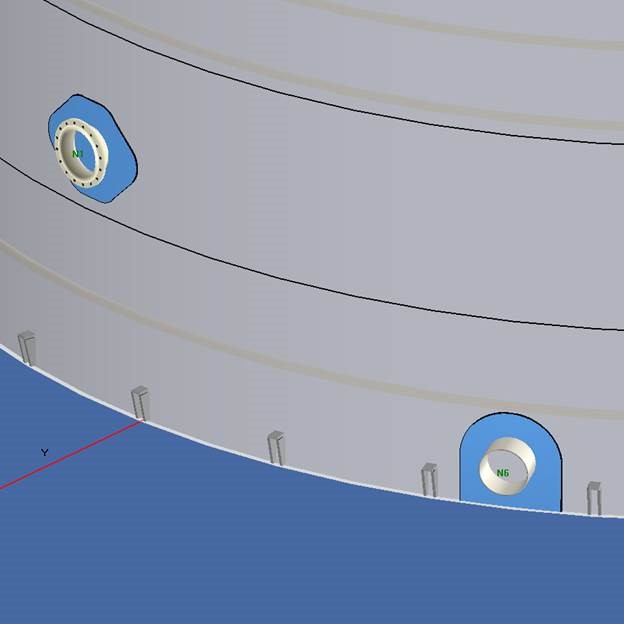

When picking the suitable devices for examination, it is vital to contemplate the specific needs of the welding procedure and the materials included. Numerous examination approaches, such as visual, ultrasonic, and radiographic screening, necessitate distinctive tools tailored to their one-of-a-kind needs. For visual evaluations, tools like amplifying calipers and glasses are critical for examining weld quality. Ultrasonic screening needs specialized devices with the ability of sending and receiving acoustic waves to discover internal flaws. Radiographic testing, on the other hand, uses X-ray or gamma-ray resources alongside delicate film or electronic detectors to expose disparities.

Furthermore, personal safety equipment (PPE) is essential to guarantee the safety and security of assessors during examinations. Choosing the right tools not just improves the accuracy of evaluations yet additionally contributes to the general honesty and safety and security of the welding task. As a result, a thorough understanding of offered devices and their applications is crucial for efficient welding assessment.

Preparing for the Evaluation Process

Prior to starting the examination process, it is important to develop a comprehensive strategy that describes the scope and purposes of the evaluation. This strategy must include particular requirements that define what constitutes acceptable high quality in the welding job being evaluated. Determining the pertinent codes and criteria is crucial, as they will lead the examination requirements and methodologies.

Furthermore, workers included in the evaluation must be appropriately educated and accredited in welding assessment methods to assure integrity and precision. A list can be valuable in arranging the numerous aspects of the examination, ranging from tools readiness to environmental problems that can affect the assessment.

Logistical considerations such as organizing, offered resources, and interaction between group participants need to be dealt with. By preparing methodically, inspectors can improve the performance of the analysis and ensure that all critical elements are properly taken into consideration prior to waging the inspection itself.

Carrying Out Visual Evaluations

Performing aesthetic inspections is a necessary action in the welding examination procedure, calling for mindful preparation to ensure effective evaluation. Assessors must recognize with essential issue signs that can signal prospective concerns in weld high quality. By focusing on these elements, one can boost the general integrity of the examination results.

Preparing for Visual Assessment

Aesthetic evaluation offers as a crucial very first step in the welding examination process, ensuring that any kind of possible defects are determined early (API 650 Welding Inspection). Correct prep work is vital for reliable visual evaluation. Assessors should begin by reviewing relevant paperwork, consisting of welding treatments and specifications, to understand the job requirements. They should collect essential tools, such as amplifying glasses, flashlights, and proper individual protective equipment (PPE) A detailed examination of the evaluation area is critical; inspectors should verify it is complimentary and clean of obstructions. Furthermore, it is essential to develop ideal lighting conditions to enhance visibility of welds. By taking these preparatory steps, examiners can produce an atmosphere for determining inconsistencies and assuring the integrity of the welded structures

Key Defect Indicators

A detailed understanding of vital issue indications is crucial throughout aesthetic examinations to guarantee the high quality and safety of welded joints. Assessors need to concentrate on certain signs such as splits, porosity, undercuts, and insufficient blend. Splits might look like sharp lines and can jeopardize architectural stability. Porosity manifests as little holes that can deteriorate weld strength. Undercuts, which are grooves along the weld edge, can lead to stress and anxiety focus. Incomplete blend indicates that the weld steel did not appropriately bond with the base material, causing a weak joint. By methodically determining these problems, assessors can identify conformity with market standards and enhance the total dependability of welded frameworks, inevitably contributing to much safer functional problems.

Executing Non-Destructive Checking Techniques

Countless non-destructive testing (NDT) strategies are integral to guaranteeing the honesty of bonded frameworks without jeopardizing their performance. These approaches allow assessors to evaluate weld top quality and detect issues without causing damage to the products being evaluated. Typical NDT techniques include ultrasonic testing, radiographic testing, magnetic particle screening, and color penetrant testing. Each approach offers a certain function, resolving various sorts of problems such as fractures, porosity, or insufficient fusion.

Applying NDT techniques requires a methodical approach, beginning with choosing the proper approach based upon the products and the nature of the weld. Training personnel in these strategies is vital for precise outcomes. In addition, establishing clear treatments and criteria assurances uniformity throughout the assessment procedure. By incorporating NDT into the welding assessment workflow, organizations can improve the dependability of their products while decreasing potential risks linked with structural failures. This positive strategy ultimately adds to preserving safety and security and high quality criteria in bonded building and constructions.

Analyzing and recording Examination Results

Effective documents and analysis of examination results are crucial components of the welding inspection procedure. Accurate documents of inspection searchings review for serve as a referral for quality guarantee and conformity with market criteria. API 650 Welding Inspection. Assessors ought to make use of electronic platforms or structured forms to log details such as the type of weld, examination techniques utilized, and any disparities determined during the evaluation

Comprehensive analysis is vital once information is collected. This involves comparing results versus check developed requirements to recognize trends or persisting issues. Analytical tools might be used to quantify flaws and analyze their impact on overall weld top quality.

Efficient communication of findings to appropriate stakeholders is crucial. Reports and recaps should be clear and succinct, highlighting vital understandings and suggestions for corrective activities. By methodically documenting and assessing evaluation outcomes, organizations can cultivate continuous renovation in welding practices and enhance item honesty.

Regularly Asked Inquiries

What Credentials Are Needed to End Up Being a Welding Inspector?

To end up being a welding inspector, one normally requires pertinent accreditations such as AWS CWI, in addition to experience in welding techniques, understanding of welding codes, and efficiency in examination strategies to assure high quality and safety and security criteria.

Just How Frequently Should Welding Inspections Be Performed?

Welding assessments ought to be conducted on a regular basis, generally after each weld is completed, and regularly during projects. Elements such as task intricacy, market requirements, and regulative requirements can affect the regularity of these examinations.

What Is the Expense of Welding Assessment Providers?

The cost of welding inspection services differs considerably based upon elements such as task intricacy, dimension, and place. Generally, prices vary from $100 to $150 per hour, with extra costs for specialized testing and qualifications.

Exist Certifications for Welding Inspectors?

Yes, there are different accreditations for welding assessors, including those provided by the American Welding Culture (AWS) and the International Institute of Welding (IIW) These certifications ensure examiners have the essential abilities and knowledge for reliable assessments.

Exactly how Do I Select an Examination Company?

To select an examination company, one need to evaluate credentials, experience, market online reputation, and client evaluations. Furthermore, comparing solution offerings view publisher site and rates can help ensure the chosen service provider meets specific project requires effectively.

Additionally, workers entailed in the assessment must be sufficiently educated and accredited in welding inspection methods to guarantee reliability and accuracy. Carrying out visual inspections is an important action in the welding evaluation procedure, needing mindful prep work to ensure efficient analysis. Visual evaluation serves as an essential very first step in the welding assessment procedure, ensuring that any kind of possible flaws are recognized early. Effective documents and evaluation of assessment outcomes are important parts of the welding inspection procedure. Welding evaluations must be carried out regularly, typically after each weld is finished, and occasionally throughout tasks.